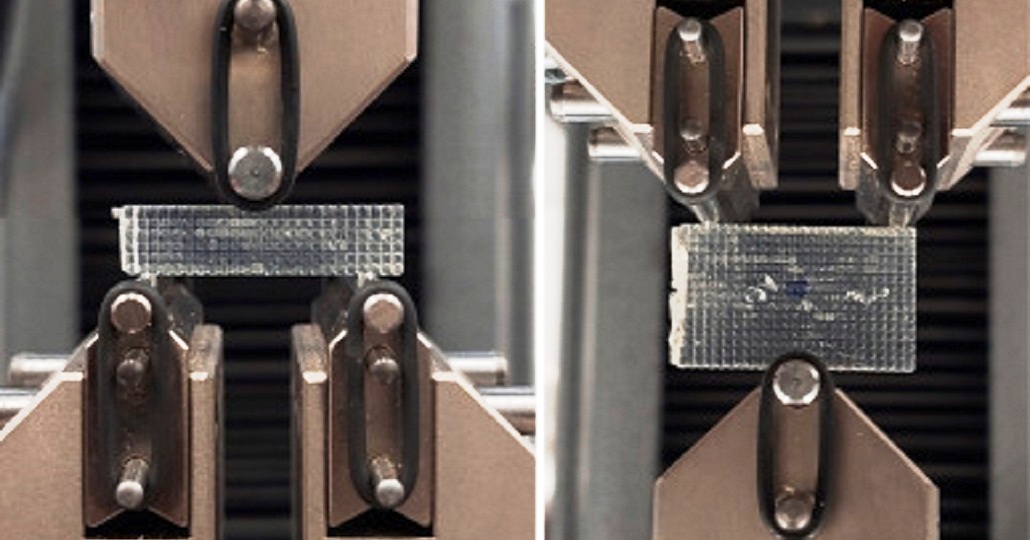

Engenharia de Materiais: Trabalho de grupo de pesquisa recebe prêmio em congresso internacional

O professor Rafael Salomão apresentou o artigo "Comportamento de concretos refratários nanoligados frente ao alumínio líquido".

OS PESQUISADORES E AS ÁREAS DE ATUAÇÃO

Os docentes da EESC - todos com nível mínimo de doutor - atuam em diferentes linhas de pesquisa da Engenharia, com alto índice de produtividade científica.

TRADIÇÃO EM ENSINO, PESQUISA E EXTENSÃO

Criada em 1953, a EESC é uma das cinco maiores unidades da Universidade de São Paulo, instituição pública de referência e bem classificada nos principais rankings internacionais.

INOVAÇÃO TECNOLÓGICA E EMPREENDEDORISMO

Programas, disciplinas, eventos e parcerias com empresas impulsionam o empreendedorismo e a inovação. O Centro EESCIn é um agente facilitador nesse processo transversal.

Área total (m2)

Edificações

Número de docentes

Funcionários Técnico-Administrativos

Departamentos

Cursos de Graduação

Alunos ativos de Graduação

Programas Strictu Sensu

Alunos ativos de Pós-Graduação

Títulos de Mestrado e Doutorado